Wiring boxes into thermal insulation

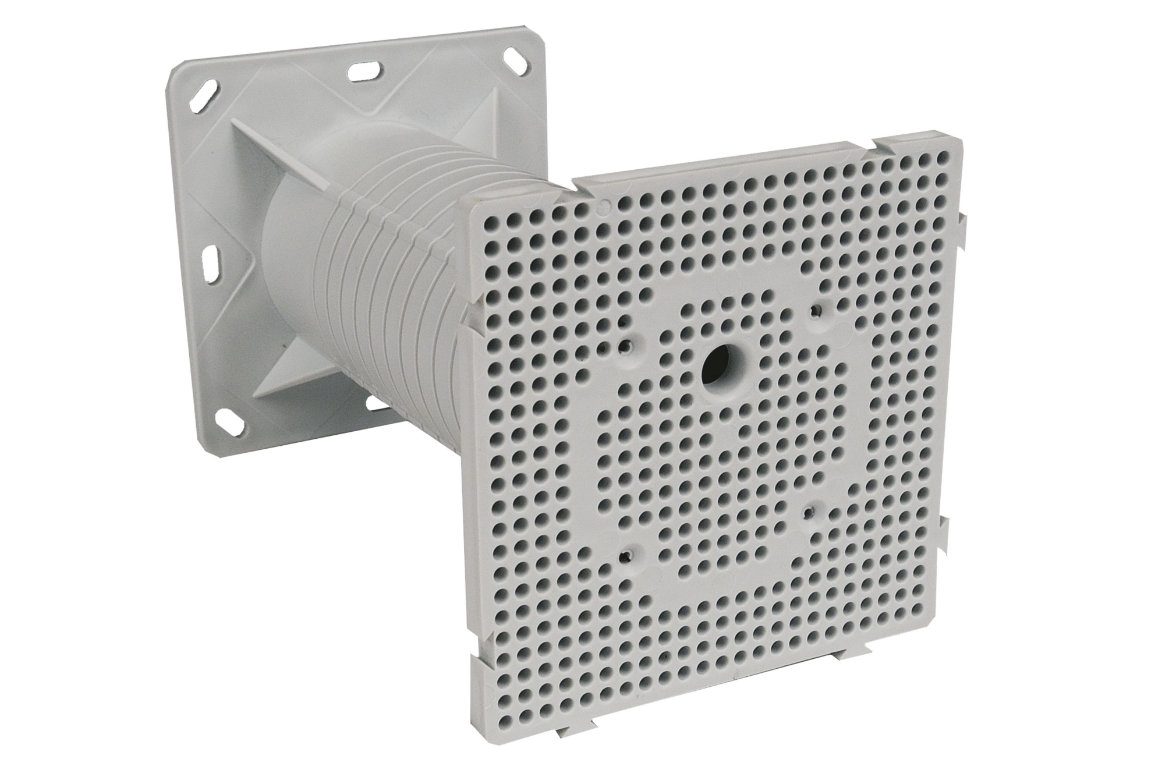

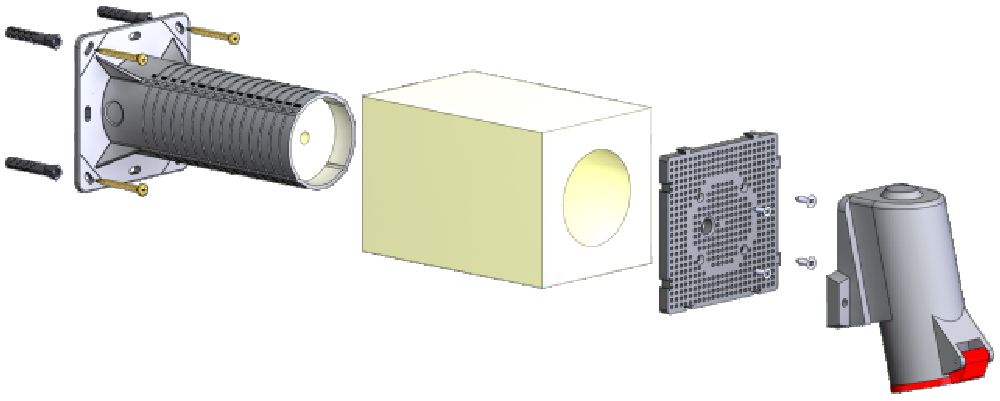

MDZ & MDZ XL

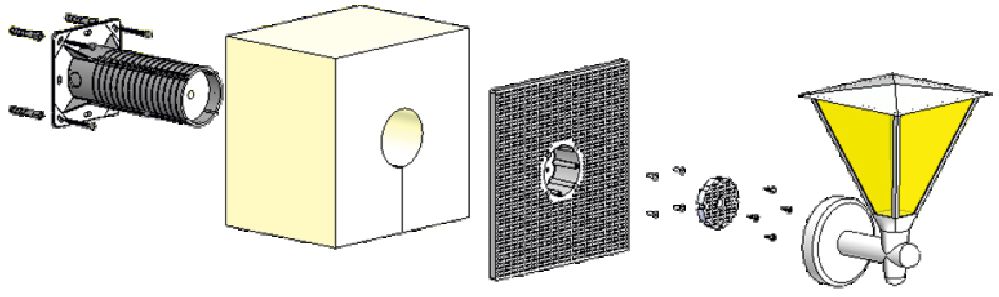

Mounting desk into thermal insulation

- for the installation of electrical devices (outdoor lights, motion sensors, 400 V sockets, etc.)

- eliminates thermal bridging

- suitable for common types of contact insulation (facade polystyrene, mineral wool)

- possible installation of the device at a thickness of 50 – 200 mm

- installation thermally insulated buildings facades with a thickness from 50 to 200 mm

- MDZ – can be conected to any mounting area

- MDZ XL – contains an integrated box designed especially for clamping, but can be used as a classic box under the switch or socket

- the package includes dowels, screws, bolts

dimension MDZ: 119x119x200mm

dimension MDZ XL: 238x238x200mm

material: self-extinguishing PP

temperature resistance: from -25 to +60 °C

load capacity: max. 4 kg

Instruction:

1. installation is done during thermal insulation installation

2. the carrier is fixed to the wall with screws and dowels depending on type of the wall surface

3. the cable is pulled through the carrier and inserts shorten insulation

4. the finally installation of box should be done by 4 added screws

5. for installation of 400 V plug we recommend chemical anchors

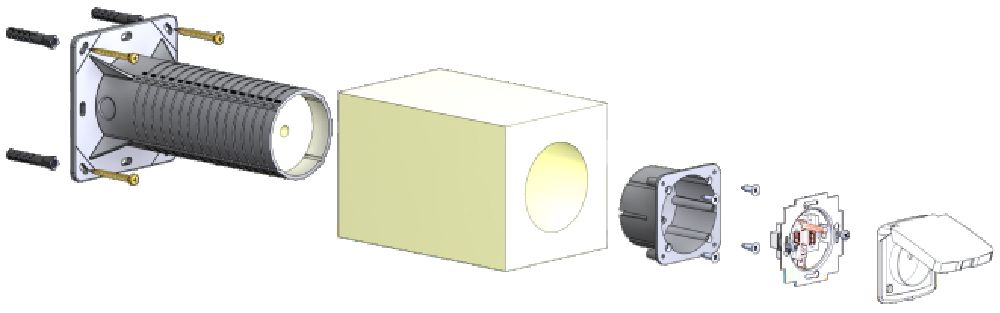

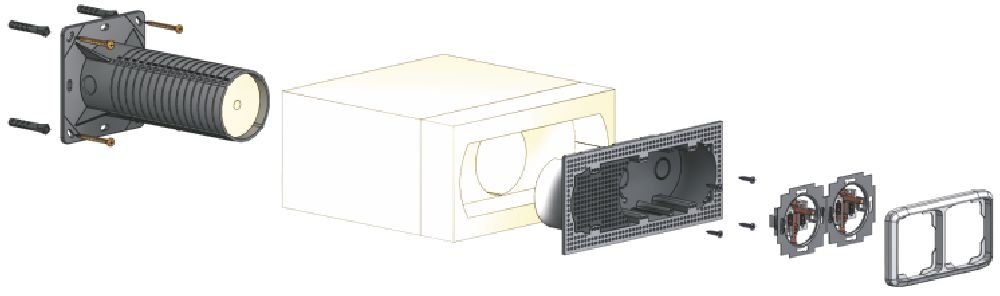

KEZ & KEZ-3

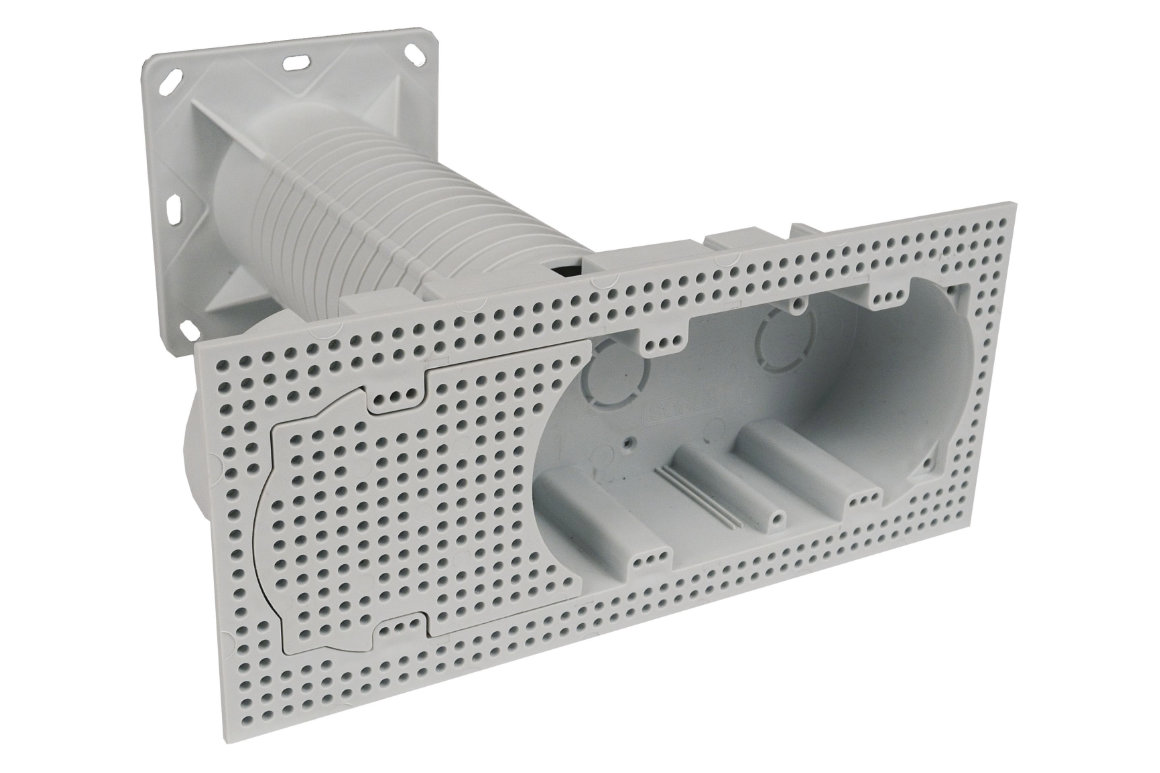

Wiring boxes into thermal insulation

- for device installation in insulated building facades

- eliminates thermal bridging

- suitable for common types of contact insulation (facade polystyrene, mineral wool)

- KEZ – for individual devices with a thermal insulation thickness 50 - 200 mm

- KEZ-3 – for double or tripled device installation in insulated building facades with thickness from 100 - 250 mm

- the package includes dowels, screws, bolts

Install the device with the appropriate environment cover. On a rough surface we recommend to seal the device with silicone.

material: self-extinguishing PP

temperature resistance: from -25 to +60 °C

Instruction:

1. installation is done during thermal insulation installation

2. It is necessary to cut the carrier including inserted insulation before installation depending on layer thickness

3. the carrier is fixed to the wall with screws and dowels depending on type of the wall surface

4. the cable is pulled through the carrier and inserts shorten insulation

5. the finally installation of box should be done by 4 added screws